Like any startup, a craft brewery can quickly grow beyond the founders’ wildest dreams. As the growing pains set in, many teams will look for ways to standardize their brewing processes, plan ahead more effectively, and analyze cost patterns to improve their profit margins. On this quest, many begin with the obvious option: a brewery cost spreadsheet.

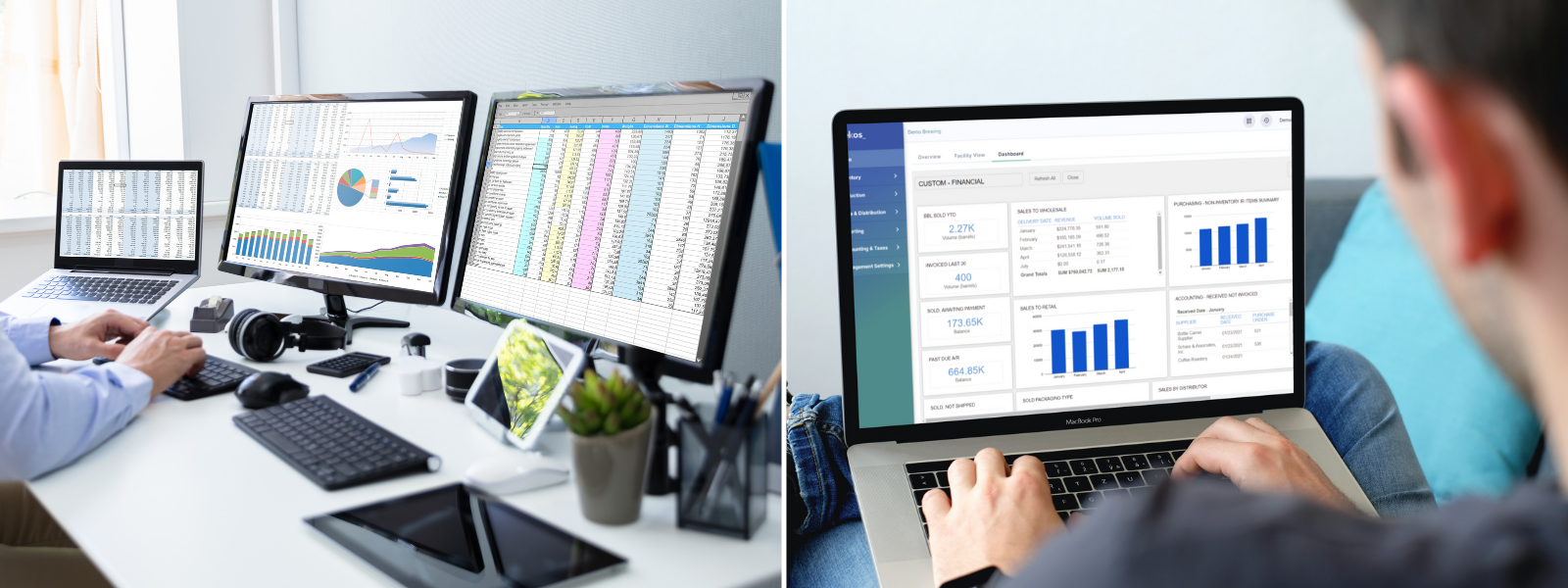

While brewery cost spreadsheets and beer inventory spreadsheets at first feel like a step toward better organization and away from the stacks of printed-out logs and notes, they can pile up just as quickly as actual paper. Soon enough, the one or two computers in the brewery’s back office are weighed down with a massive number of files. Locating the information you need — let alone ensuring its accuracy and sharing it with the right people — becomes a full-time job that nobody wanted.

If you’ve been on the hunt for these types of templates, take a step back and think about what you’re trying to accomplish. Let’s look at some of the most common problems breweries try to solve with brewery cost spreadsheets and other types of spreadsheets to see how they measure up as business management solutions.

Table of contents

1. Scaling Beer Recipes & Tracking Fermentation Metrics

You’re looking for a beer recipe calculator or brewing log sheet.

As demand for your products grows, you may look to scale single-turn recipes into multi-turn recipes to increase your production capacity. A spreadsheet or well-built online tool could certainly accomplish the simple task of scaling the recipe for you — so what’s the issue? Your list of recipes will likely grow significantly over time. Storing each one in a brewing log sheet and manually calculating the scaled-up versions will take up time that could be better spent sourcing the perfect ingredients and testing product quality. You’re better off using software that has recipe management features built in, allowing you to plan for the long haul rather than finding a temporary solution.

With such a system, you can also track metrics for each batch digitally in professional brew logs, allowing you to easily look back at previous versions of your flagship beers and compare to current batches. Again, while a brewing log sheet (printed or digital) may work when you’re first starting out, recording these metrics in a unified system allows for easier accessibility among different team members and makes it easier to find the information you need quickly.

2. Creating a Production Schedule

You’re looking for a brewing schedule spreadsheet or brewery production spreadsheet.

We’ve seen many breweries create production schedule spreadsheets with complicated color-coding systems and display them on TVs around the production floor for employees to reference. They can be onerous to build and even more frustrating to maintain as different fields are accidentally erased and formulas become glitchy. Plus, brewing spreadsheets don’t automatically connect to any kind of task management system, so if you want to send reminders to employees responsible for different parts of the production process, you’ll need to manage that separately.

A brewery-specific production management system is better suited for growing teams that want to stay organized and get better at planning ahead. You can connect everything at the batch level — recipes, related tasks for different team members, equipment, inventory, and more. With Ekos specifically, you can even get a birds-eye view by using the floorplan view of the production floor.

3. Managing Raw Ingredients & Finished Goods Inventory

You’re looking for a brewery inventory spreadsheet.

One of the biggest issues teams without software run into is tracking raw ingredient inventory and remembering to order additional materials before they need them. Keeping up with inventory additions and depletions accurately in a brewery inventory spreadsheet is difficult — erasing a value in a cell or changing information in the wrong column is too easy. Plus, deciding when you need to reorder requires either a steel-trap memory of the quantity you need for every item or a spreadsheet with a lot of sections, complicated formulas, and glitchy color-coding. With software, you can set reorder points and get notifications when something is running low. That way you avoid downtime and the costly expedited shipping costs that are required if you wait until the last minute.

But inventory management involves a lot more than just ingredients. You might be looking for a beer inventory spreadsheet to track finished goods like kegs, cans, and bottles. Besides the issues we’ve already mentioned, inventory spreadsheets don’t connect to any other part of your business, so you have to manually update them when a sale is made. With an inventory management system, beer inventory is automatically depleted after your sales team posts an invoice or even after a packaged beer sale is made in the taproom. Say goodbye to the hours spent manually reconciling sales and inventory, just to discover you sold something you don’t have on hand.

“I was going to have to hire a full-time accountant just to deal with inventory. When Ekos came along, it allowed me to focus on the big picture of growing the brewery instead of looking at brew sheets.”

– Mark Huizink, Founder, 2 Crows Brewing

And when it comes to wholesale sales, don’t even bother with a keg inventory spreadsheet. Save yourself the headache of tracking down your sales reps or delivery drivers and asking when they last delivered a keg to a customer. Keg tracking software that connects to your core brewery management system helps you see when a keg was sold, what was in it, and whether you’ve gotten it back so you never have to guess where it is again.

4. Analyzing Brewery Costs

You’re looking for a brewery cost spreadsheet or brewery accounting spreadsheet.

You want to be more intentional about reviewing your brewery’s financial metrics on a regular basis and keeping an eye on costs and margins. That makes sense. What doesn’t make sense is expecting a brewery cost spreadsheet to provide all the information you need in an efficient manner.

“You’ve got to have your head wrapped around your cost of goods sold or you’re doing yourself and your whole team a disservice.”

– Andrew Nations, founder and president, Great Raft Brewing

Here’s the deal: If you want to improve business visibility and get a more accurate picture of your cost of goods sold (COGS) and how to price beer, you and the rest of your team must painstakingly record inventory, production, and sales data every day as you’re completing tasks. There’s no way around it. And the reality is that spreadsheets are not the best way to do this accurately in real time.

For one, a small typo in any one of these spreadsheets can make your bottom-line financial metrics inaccurate and, therefore, useless. With brewery management software, you have one primary system of record where every action by any user leaves a trace. You won’t lose a vital piece of information to one tiny accidental keystroke.

What’s more, you can use reports built into the software to quickly see the metrics you’re looking for with up-to-the-minute data. By contrast, how often will your team take the time to sit down in the office and fill out a spreadsheet?

“The one thing Ekos does really well is that it’s fully transactional, much like an accounting system. It’s not easy to go in and accidentally delete stuff and if you do, it leaves a record. In a spreadsheet, I can make changes and you wouldn’t know. In Ekos it’s more transparent.”

– Adam Crandall, co-founder of Moody Ales

Ditch Brewery Cost Spreadsheets for Good

Manual processes, pen-and-paper note-taking, and spreadsheets are slowing you down. Ekos helps you digitally manage your data through software so you can spend less time at your computer and more time making beer.

Ekos is the only brewery management software that connects your back office to your front office so you can manage your entire brewery — from inventory and production to sales and accounting — in a single system. If you’ve been using spreadsheets for years, you’ll wonder what took you so long to make the switch.

“I wouldn’t start a brewery without Ekos. Whatever you do, don’t use spreadsheets!”

— Brian Stephan, co-founder, Iowa Brewing Company

Learn more about our capabilities or get in touch with our team today.